TOKYO, January 15, 2021 — Ube Industries, Ltd. and the Port and Airport Research Institute (PARI), part of Japan’s National Institute of Maritime, Port and Aviation Technology , today announced that a research paper on the results of their joint study and analysis of the deterioration of cement mortar specimens in deep sea has been published in an international science journal, a first-ever achievement.

Deep-sea exposure testing of cement mortar specimens and analysis of them after exposure were conducted by Ms. Kobayashi1, Dr. Takahashi1 and Dr. Kawabata2. As momentum for marine development grows around the world, the research findings are expected to contribute to increased utilization of cement-based materials in the extreme and unique conditions found in the deep sea, as well as to the creation of construction technologies for marine infrastructure.

1 Cement Development Department, Technical Development Center, Construction Materials Company, Ube Industries;

2 Frontier Technologies for Structures Group, Port and Airport Research Institute

The deep sea is last frontier on our planet, and recent technological advancements have led to the discovery of various marine resources, which are now being studied for development. Utilization of marine energy resources such as offshore wind and tidal energy is being actively promoted. Given these circumstances, construction of marine structures in the deep sea is expected to occur in the future, accompanied by utilization of cement materials with excellent versatility and durability for such applications.

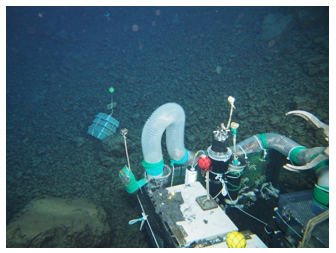

The research was undertaken in order to elucidate the changes in the mechanical properties and hydrate phases of cement specimens in the deep sea. From December 2015 to July 2017, the researchers conducted exposure testing on cement mortar specimens (hereafter “specimens”) placed at a seafloor depth of approximately 1,680 meters in a location approximately 60 kilometers from Tarama Island in Okinawa Prefecture (Fig. 1). The specimens were placed and salvaged with the help of the Japan Agency for Marine-Earth Science and Technology (JAMSTEC) and Kochi University. The conditions are extreme compared with shallow seas, with a hydraulic pressure of 17 MPa and water temperature of 4 ℃.

Upon salvaging the specimens after 608 days of exposure, the surface of the specimens was observed to have significantly changed (Fig. 2), with the structure having softened so much that some of the surface disintegrated at the touch of a hand. Furthermore, compressive strength testing of the specimens confirmed a significant decrease in strength compared with pre-exposure.

Analysis of the specimens after exposure testing revealed significant leaching of the main constituent calcium, beyond what would be anticipated from shallow sea conditions. Furthermore, carbonate, sulfate, and magnesium ions from seawater had diffused into the specimens, precipitating secondary hydrates without binding capacities. The researchers concluded that these processes caused the surface of the specimens to soften and become mashy, leading to changes in the physical properties of the specimens, including decreased compressive strength.

The research was mainly focused on observing chemical deterioration. More detailed verification of the damage to specimens from high hydraulic pressures in deep sea is needed. In the future, the researchers plan to study the relationship between the effects of high hydraulic pressures and the resulting chemical deterioration.

Testing on the use of cement materials in the extreme and unique environment of the deep sea has just begun. It is anticipated that there will be future needs for multidisciplinary R&D and technology formation including in the areas of materials design, construction methods, and structural design methodologies. Ube Industries and PARI intend to expand their collaboration with Japanese and international universities and research institutes in order to conduct further R&D and establish technologies.

The research paper will be published in Volume 142 of the scientific journal, Cement and Concrete Research, which is available online from January 15, 2021.

Title: Physicochemical properties of the Portland cement-based mortar exposed to deep seafloor conditions at a depth of 1,680 m