Basic Approach to Environmental Preservation Initiatives

The UBE Group strives to keep environmental accidents to zero by working to reduce environmental risks. The Group also engages in continuous activities to reduce its environmental impact in order to help ensure sustainable social progress.

The UBE Group also responds to global environmental issues by ensuring that its corporate activities are in harmony with nature and helping to resolve climate change, conserve biodiversity, address the issue of marine plastics, and conserve water resources.

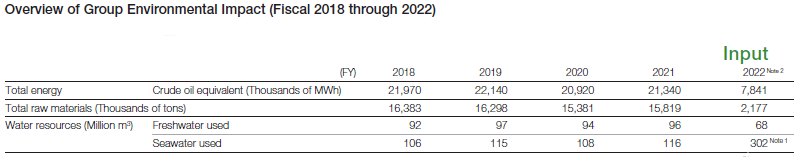

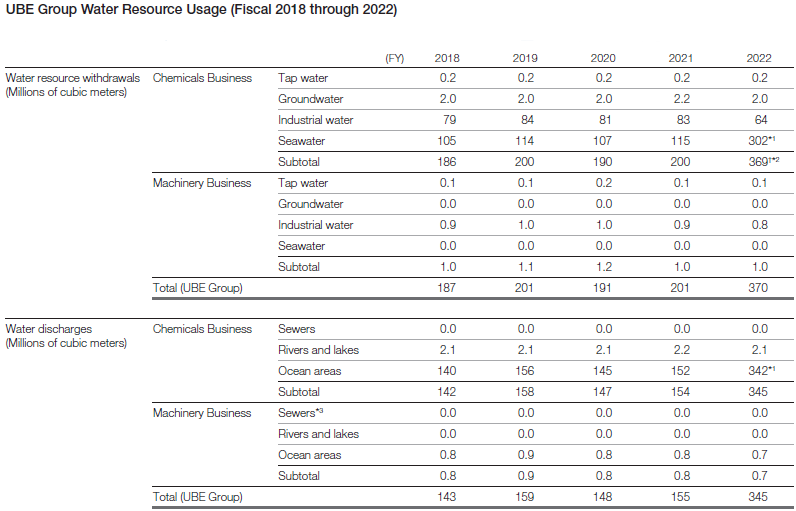

Environmental Performance

The UBE Group is committed to extensively managing atmospheric and water emissions of pollutants and contaminants, and endeavors to comply with agreements and voluntary standards. We are endeavoring to lower our environmental impact, managing it by checking progress with reduction plans in strategic management meetings and undertaking PDCA cycles. We will keep pursuing business activities that contribute to a circular economy by tackling environmental issues, lowering and using industrial waste, and constraining chemical substance emissions.

Notes:

Notes:1. Fiscal 2022 data includes cooling seawater for private power generation.

2. Fiscal 2022 data excludes the former Construction Materials Company.

Data covers UBE factories, laboratories, and key domestic consolidated subsidiaries with factories shown on page 16 of Integrated Report Supplementary Information (Environment and Safety / Quality Assurance)![]() , representing 70% of such subsidiaries.

, representing 70% of such subsidiaries.

- *1 Sulfur oxides (SOx) originate in the sulfur (S) component of fuels. Boilers are our main source of these oxides.

- *2 Nitrogen oxides (NOx) stem from fuel combustion, primarily from Group boilers and cement kilns.

- *3 Pollutant Release and Transfer Register (PRTR) Law: This legislation requires companies to identify business site chemical substance emissions and transfer volumes and report to the government. The Ministry of the Environment discloses the submitted information on its website. Such disclosure is designed to encourage voluntary efforts to improve chemical substance management.

- *4 Chemical Oxygen Demand (COD): This is an indicator of water pollution by organic substances and represents the amount of oxygen consumed in the chemical oxidation of organic matter.

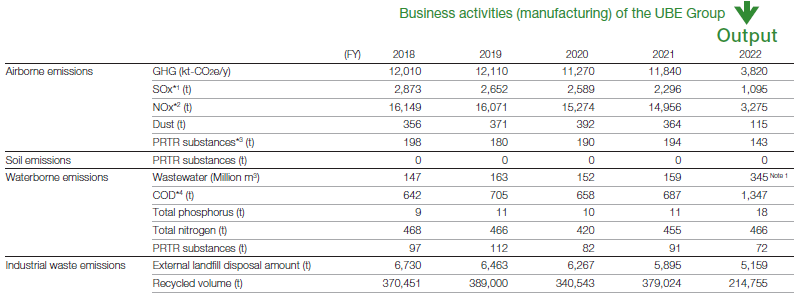

Environmental Accounting

- *1 Sulfur oxides (SOx) originate in the sulfur (S) component of fuels. Boilers are our main source of these oxides.

- *2 Nitrogen oxides (NOx) stem from fuel combustion, primarily from Group boilers and cement kilns.

- *3 Pollutant Release and Transfer Register (PRTR) Law: This legislation requires companies to identify business site chemical substance emissions and transfer volumes and report to the government. The Ministry of the Environment discloses the submitted information on its website. Such disclosure is designed to encourage voluntary efforts to improve chemical substance management.

- *4 Chemical Oxygen Demand (COD): This is an indicator of water pollution by organic substances and represents the amount of oxygen consumed in the chemical oxidation of organic matter.

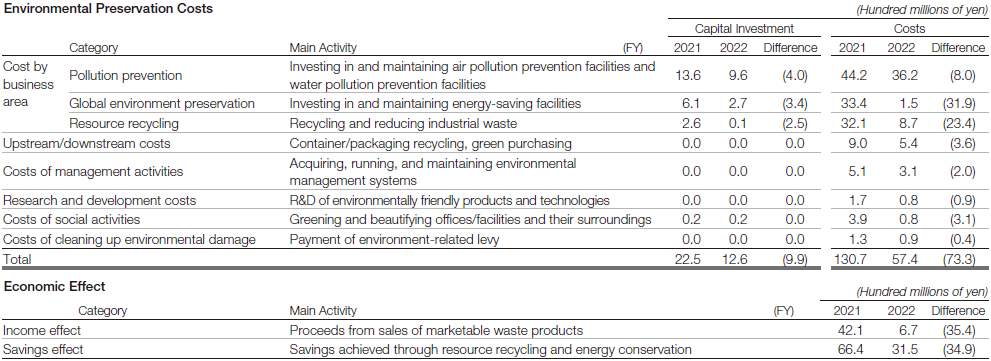

Water Resource Usage

We installed pollutant monitoring facilities to manage the quality of water discharges into bodies of waters water. We maintain facilities to treat plant wastewater that could cause significant pollution.

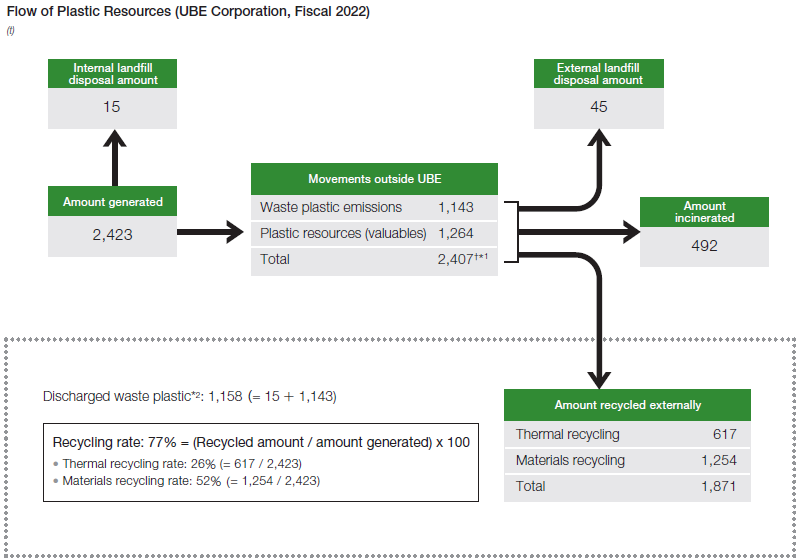

*1 Including in-house internal landfill disposal and recycled amount that are subject to calculation under the Plastic Resource Circulation Act

*1 Including in-house internal landfill disposal and recycled amount that are subject to calculation under the Plastic Resource Circulation Act*2 The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.

*3 Wastewater volume 10,000 m3 or less

Data covers UBE factories, laboratories, and key domestic consolidated subsidiaries with factories shown on page 16 of Integrated Report Supplementary Information (Environment and Safety / Quality Assurance)![]() , representing 70% of such subsidiaries.

, representing 70% of such subsidiaries.

Emissions Data by Facility

- * We reorganized or renamed these sites in fiscal 2022 or 2023. See Reorganizations and Renamings on page 16 of Integrated Report Supplementary Information (Environment and Safety / Quality Assurance)

.

.

Data covers UBE factories, laboratories, and key domestic consolidated subsidiaries with factories shown on page 16 of Integrated Report Supplementary Information (Environment and Safety / Quality Assurance) , representing 70% of such subsidiaries.

, representing 70% of such subsidiaries. - *1 Sulfur oxides (SOx) originate in the sulfur (S) component of fuels. Boilers are our main source of these oxides.

- *2 Nitrogen oxides (NOx) stem from fuel combustion, primarily from Group boilers and cement kilns.

- *3 Chemical Oxygen Demand (COD): This is an indicator of water pollution by organic substances and represents the amount of oxygen consumed in the chemical oxidation of organic matter.

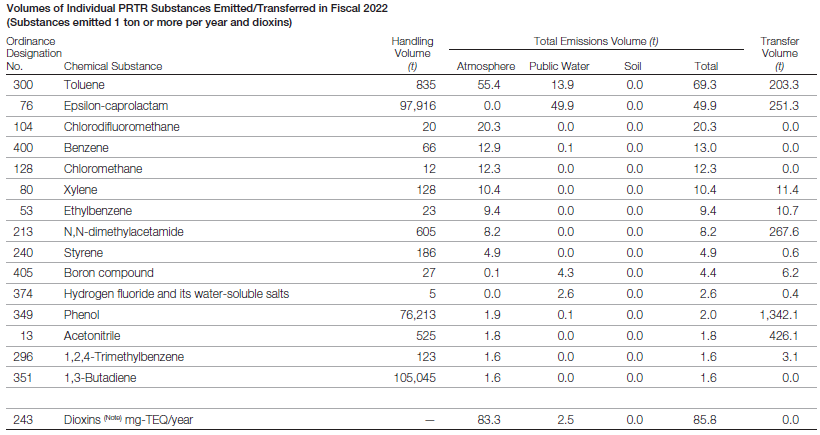

Suppressing Chemical Substance Emissions

Total Emissions of 20 Chemical Substances

Fiscal 2024 Target: 32% reduction from fiscal 2010 level

The UBE Group accorded Companywide priority to 20 key chemical substances*3 with high emission volumes from among those subject to the PRTR Law*1 and VOCs*2, and endeavors to control their emissions. In fiscal 2022, we reduced the total emissions of 20 chemical substances by 38% from the fiscal 2010 level (in terms of PRTR substances and VOC emissions reductions, as shown above, down 56% and 50%, respectively, from fiscal 2010). The reduction target for fiscal 2024 is 32%. We will continue to cut our emissions.

Data covers UBE factories, laboratories, and key domestic consolidated subsidiaries with factories shown on page 16 of Integrated Report Supplementary Information (Environment and Safety / Quality Assurance)![]() , representing 70% of such subsidiaries.

, representing 70% of such subsidiaries.

Note: Contains various compounds

Note: Contains various compoundsScope of coverage: UBE’s domestic plants and laboratories and key domestic consolidated subsidiaries with plants (see page 16), representing 70% of such subsidiaries

- *1 Pollutant Release and Transfer Register (PRTR) Law: This legislation requires companies to identify business site chemical substance emissions and transfer volumes and report to the government. The Ministry of the Environment discloses the submitted information on its website. Such disclosure is designed to encourage voluntary efforts to improve chemical substance management.

- *2 Volatile organic compounds (VOCs): These organic chemicals evaporate or sublimate easily, entering the atmosphere as gases. They are factors in the forming of suspended particulate matter (PM) and photochemical oxidant pollution.

- *3 20 chemicals selected independently: Methyl alcohol, butyl alcohol, toluene, epsilon-caprolactam, styrene, ammonia, cyclohexane, cyclohexanone, oxalic acid, vinyl acetate, xylene, n-hexane, ethylbenzene, chloromethane, benzene, dimethyl phthalate, N,N-dimethylacetamide, boric acid compound, phenol, hydrogen fluoride and its water-soluble salts

Establishing a Recycling-Based Society

Using Resources Effectively

*1 The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.

*1 The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.*2 Including in-house internal landfill disposal and recycled amount that are subject to calculation under the Plastic Resource Circulation Act

The Plastic Resource Circulation Act, which went into effect in April 2022, requires businesses to minimize and recycle waste plastic. UBE’s efforts to use plastic resources effectively resulted in a 77% recycling rate in fiscal 2022. We will continue to push ahead with plastic recycling.

Data covers eight UBE business sites. These are the Sakai Factory, Ube Chemical Factory, Ube Chemical Factory Fujimagari Area, Ube Electronic and Industrial Materials Factory, Ube Research Laboratory, Pharmaceutical Research Laboratory, Future Tech Laboratory, and Osaka Research & Development Center.

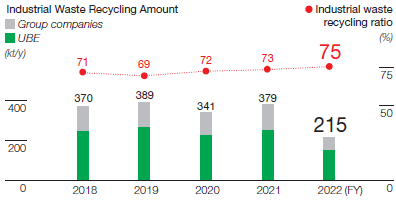

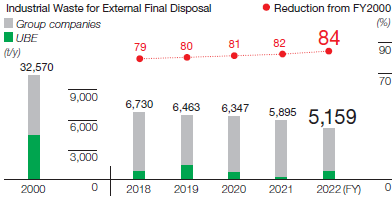

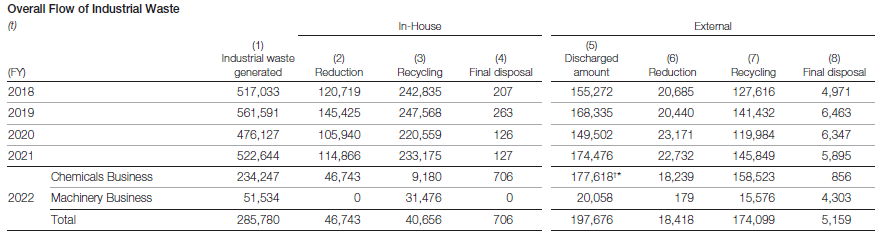

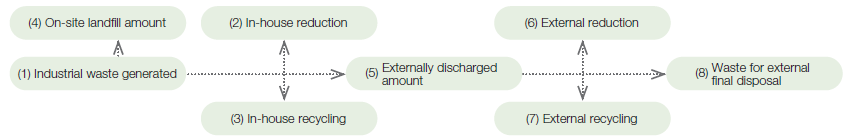

Reducing Industrial Waste

Waste for External Final Disposal

Fiscal 2024 target: 87% reduction from fiscal 2000 level

The UBE Group is reducing and recycling industrial waste to help create a circular economy. Our medium-term goal is to cut external final disposal by 87% from the fiscal 2000 level by fiscal 2024. We have taken steps to reach that target. In fiscal 2022, our external landfill disposal amount was 84% below that of fiscal 2000. We will keep striving to reduce industrial waste.

* The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.

* The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.Scope of coverage: UBE’s domestic plants and laboratories and key domestic consolidated subsidiaries with plants. See page 16 for details.

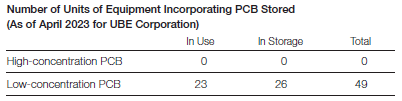

Polychlorinated Biphenyl (PCB) Waste Disposal

We thoroughly audit stabilizers and other equipment using PCBs. In addition, we are endeavoring to complete PCB waste disposals by the deadline set under the amended Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes. We comply with storage and disposal laws and ordinances processing, and utilize Japan Environmental Storage & Safety Corporation (JESCO) and certified detoxification contractors to systematically dispose of PCB waste.

UBE Corporation completely disposed of high-concentration PCB waste in fiscal 2021. It is endeavoring to systematically collect and dispose of all low-concentration PCB waste by the deadline set under the amended Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes.