UBE Group Policy for Achieving Carbon Neutrality by 2050

Taking a further step forward from the UBE Group Environmental Vision 2050 that was announced in May 2020, the UBE Group in April 2021 announced a policy to achieve carbon neutrality by 2050. The policy calls for the UBE Group to achieve net-zero emissions of greenhouse gases (GHGs) from its business activities. The Group will also strive to help the broader society become carbon neutral by pursuing R&D for products and technologies that are beneficial for the environment and the practical application of eco-friendly innovations. The UBE Group will work as a leading solution provider to help realize a decarbonized society.

UBE Group Policy for Achieving Carbon Neutrality by 2050

- 1. Achieve carbon neutrality for the Group’s business activities (minimizing GHG emissions and developing innovative technologies), by:

-

- Practicing rigorous energy conservation and making process improvements

- Maximizing the use of CO2-free energy

- Realigning the business structure to reduce dependency on fossil resources (minimize the use of fossil resources)

- Pursuing R&D and bringing products to market in fields such as CO2 utilization technology and non-fossil raw materials

- 2. Help the broader society become carbon neutral, by:

-

- Supplying products that, when used, contribute to reduction of CO2 emissions

- Contributing to reduction of CO2 emissions in customer supply chains (supplying products such as biomass-derived polymers, biodegradable polymers, and polymers with both of those properties, as well as recycled and re-used chemicals)

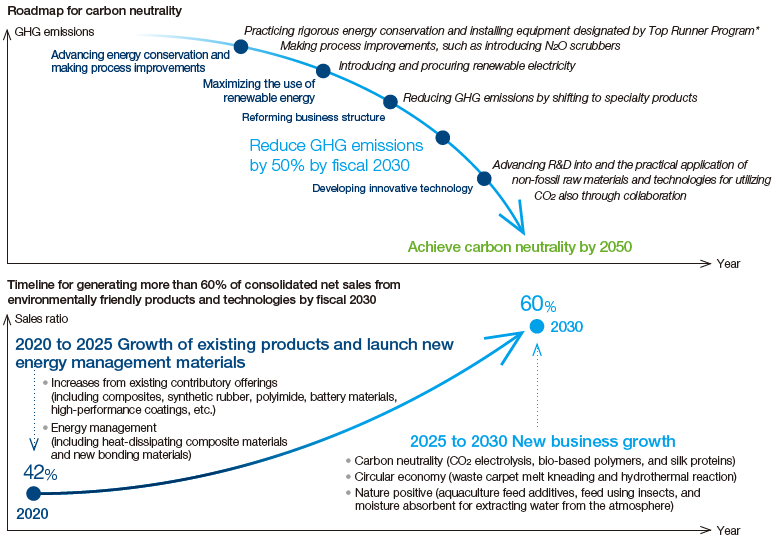

UBE Group Announces New Medium-Term Targets by 2030 for Achieving Carbon Neutrality by 2050

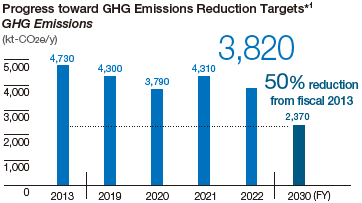

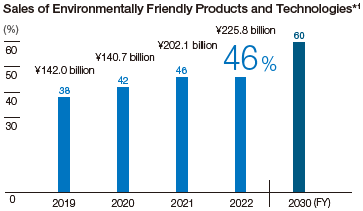

In April 2022, the UBE Group has revised its medium-term environmental targets for fiscal 2030 and set new targets to reduce greenhouse gas (GHG) emissions by 50% by fiscal 2030 (compared to fiscal 2013) and raise the share of environmentally friendly products and technologies it sells to at least 60% of consolidated net sales.

In 2021, the UBE Group announced its Policy for Achieving Carbon Neutrality by 2050, setting out the goal of achieving net-zero emissions of GHGs from its business activities. Also, as medium-term targets on the road to carbon neutrality, the group set the targets of achieving an 20% reduction in GHGs emissions in the chemicals segment by 2030 (compared to fiscal 2013).

The UBE Group, which spined-off and transferred its cement business to Mitsubishi UBE Cement Corporation and shifted to a business portfolio focused on the specialty chemicals business, reviewed its previous targets. The Group further strengthen its efforts to address global environmental issues, and strive to help the broader society become carbon neutral.

Fiscal 2030 Targets

- GHG emission reduction targets:

50% reduction compared to FY2013 (previously 20% reduction in the chemicals segment) - Target percentage of consolidated net sales comprising environmentally friendly products and technologies:

60% or more (previously 50% or more)

Measures for Carbon Neutrality

- Advancing energy conservation and making process improvements

The Group will minimize the use of fossil resources by continuously working on practicing rigorous energy conservation and making process improvements. - Maximizing the use of renewable energy

The Group will maximize the use of renewable energy by introducing solar power generation systems in its factories and procuring electricity generated by utilizing renewable energy such as wind power, solar power and biomass power. - Reforming business structure

The shift to specialty products, which have a relatively low energy burden, will help reduce the Group’s GHG emissions by minimizing the use of fossil resources, and will also facilitate the development of a resilient business structure that is not greatly influenced by market conditions for raw materials and fuel. The UBE Group aims to create a business structure with a low environmental impact focused on specialty products to drive profitability and growth potential, while creating high added value for basic chemicals and carrying out business structure reforms. - Innovative technology development

Innovative technological development is essential to achieving carbon neutrality by 2050. Accordingly, with a medium- to long-term outlook, the Group will also work on research and development into and the practical application of non-fossil raw materials and technologies for utilizing CO2, and these efforts may involve collaboration with other companies.

Percentage of consolidated net sales comprising environmentally friendly products and technologies

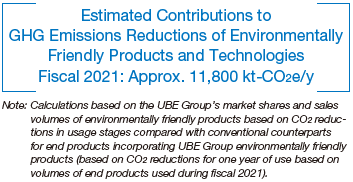

The UBE Group has formulated guidelines based on the revised ISO 14001:2015, and has defined environmentally friendly products and technologies. The Group aims to help the broader society become carbon neutral by further driving the development of environmentally friendly products and technologies and providing them to more customers.

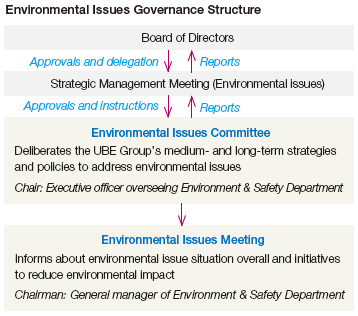

Governance Structure

The UBE Group established the Environmental Issues Committee to identify and act on problems in that regard. The President and CEO chairs Strategic Management Meeting, which receives deliberation reports from the Environmental Issues Committee, provides instructions as needed, and constantly monitors countermeasures progress. A report on important matters goes to the Board of Directors once annually.

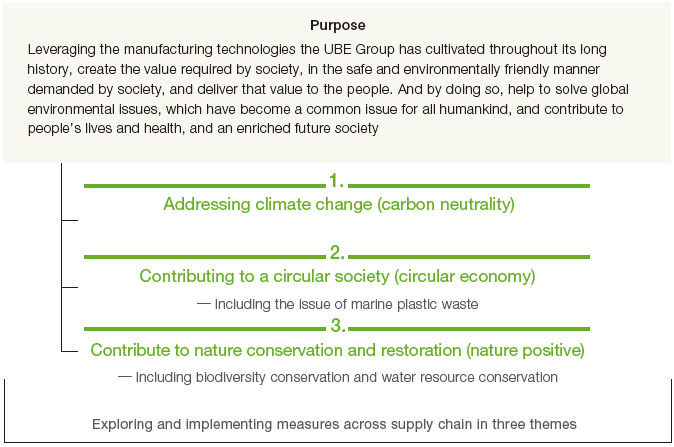

Basic Guidelines for Addressing Global Environmental Issues

The UBE Group focuses on responding to climate change (carbon neutrality), and on contributing to a circular economy and nature conservation and restoration (nature positive). We are helping resolve environmental issues by steadily implementing strategic measures. These include reducing GHG emissions across the value chain, providing environmentally friendly products, technologies, and services, and engaging with stakeholders.

Basic Activities Policy on Environmental Issues

To realize “Addressing climate change (carbon neutrality),” “Contributing to a circular society (circular economy),” and “Contributing to nature conservation and restoration (nature positive),” we have formulated the following strategies and KPIs and are steadily implementing them.

- Ensuring that the management cycle works properly by analyzing materiality, identifying risks and opportunities, formulating strategies and KPIs, and disclosing information

- Minimizing the impacts of internal operations

- Continuing to engage

- Reach out to entire value chain (suppliers, employees, customers, investors, and communities) to resolve issues in everything from product and services purchases to in-house manufacturing and product processing, usage, and disposal

- Disclose information appropriately to all stakeholders and encourage collaboration to resolve environmental issues

1. Addressing climate change (carbon neutrality)

【Strategy】

- Reduce internal GHG emissions.

- Keep developing and providing environmentally friendly products and technologies that help cut GHG emissions.

【Targets and Business Plan】

We have formulated a business plan that encompasses overhauling our business structure reforms and deploying measures to conserve energy so we can reach our fiscal 2030 target of halving GHG emissions from fiscal 2013 levels to aim for becoming carbon neutral by 2050.

【Significance】

- The increase of GHG emissions into the atmosphere due to human activities is causing global warming and major changes in the climate.

- This could transform the natural environment and degrade ecosystem services. Rapid climate change could profoundly affect lives and businesses. It is our social responsibility and mission to tackle these changes as swiftly as possible.

【Initiatives】

Please see Addressing Climate Change (Carbon Neutrality) on pages 54–55.

2. Contributing to a circular society (circular economy)

【Strategy】

We will tap discarded and other resources effectively and recycle them. We will develop and provide circular materials, products, and technologies.

【Targets and Business Plan】

Our goal is to increase the sales ratio of environmentally friendly products and technologies, including products that contribute to the realization of a circular economy, to 60% by 2030. In addition, we aim to effectively utilize and reduce waste such as plastics generated by our own operations.

3. Contribute to nature conservation and restoration (nature positive)

【Strategy】

We will identify the impacts and dependencies of our business activities on nature, identify risks and opportunities, and contribute to the conservation and restoration of the natural environment and the sustainable use of ecosystem services. We also provide products, technologies, and services that help realize nature positive.

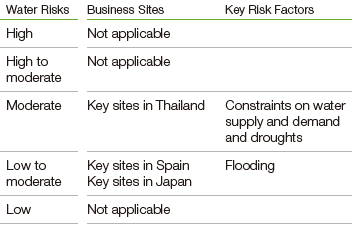

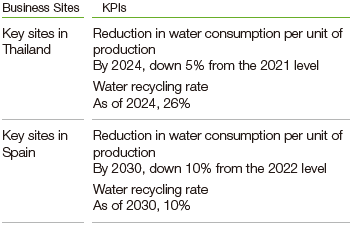

【Targets and Business Plan】

- Water sources: We analyze water stress trends based on the water conditions (context) and water supply and demand scenario at each site. At sites where water stress is expected to rise, we will reduce water withdrawal and improve water recycling rates by formulating water use strategies and monitoring KPIs.

- Environmental impacts of our operations, including from air, water, and soil pollution: We monitor and reduce pollutant emissions to eliminate environmental incidents.

- Engagement: We will work with the supply chain (environmental impact assessment), employees (education), customers (provision of environmentally friendly products and technologies), investors (provision of information and exchange of opinions), and local communities (environmental improvement activities). We will verify adverse effects (trade-offs) on the natural environment and minimize negative impacts.

【Significance】

A lot of the products, services, and energy supporting our lives are the fruits of nature. Protecting the environment, restoring nature, and preserving ecosystem services will help safeguard our living environment and livelihoods. Nature conservation and restoration can reduce weather related disasters while protecting cultures and traditions, landscapes, and our diets.

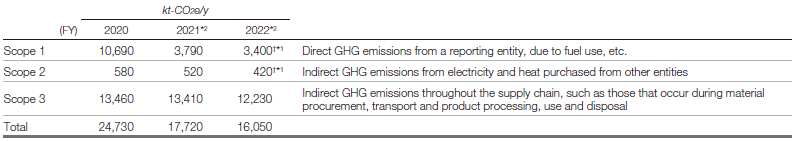

Addressing climate change

Initiatives to Reduce GHG Emissions

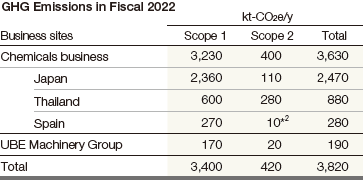

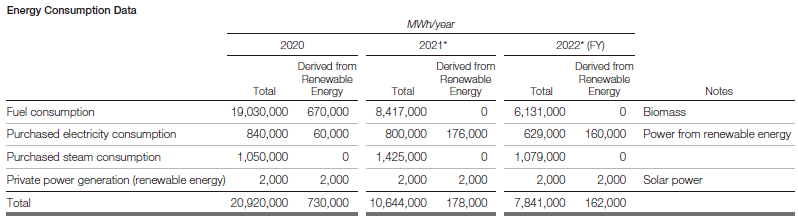

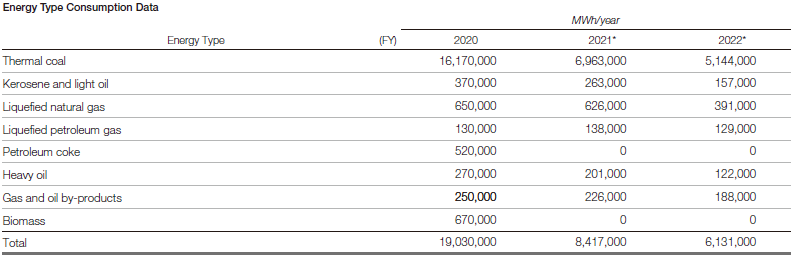

*1 Excluding cement-related business transferred to Mitsubishi UBE Cement Corporation.

*1 Excluding cement-related business transferred to Mitsubishi UBE Cement Corporation.*2 Electricity purchased from external sources was renewables based.

Note: Numbers may not add up due to rounding.

Note: Numbers may not add up due to rounding.

Commitment Letter Submitted to Science Based Targets Initiative

In March 2023, the UBE Group submitted a commitment letter to the Science Based Targets initiative. We made this move to secure certification from that body for our targets for reducing GHG emissions across our supply chain over the next five to 10 years in keeping with the criteria of the Paris Agreement, an international treaty on climate change. We made this move in view of growing interest in environmental protection and sustainability in recent years. Our efforts to reduce our environmental impact extend beyond in-house operations to encompass our whole supply chain, from raw materials procurement through product use and disposal.

Deploying System to Calculate Product GHG Emissions Data

UBE and NTT DATA Japan Corporation jointly created a system to calculate product GHG emissions. In January 2023, we began providing data from that system to customers. This information makes it easy for customers to assess GHG emissions across their supply and value chains and contribute to efficiently implement measures to reduce these emissions.

We are using this system for some Ube Chemical Factory offerings, and look to extend its product and plant coverage.

Participating in GX League’s Emissions Trading Scheme

In October 2022, we announced our endorsement of the GX (for green transformation) League. Japan’s Ministry of Economy, Trade and Industry leads that initiative, which aims to reach the nation’s GHG emissions goals by 2030 and achieve carbon neutrality by 2050. We also announced our participation in the league’s voluntary emissions trading schemes, which will be fully operational from 2026. We consider our involvement in the league an opportunity to grow sustainably by reducing our GHG emissions while becoming more competitive.

Initiatives to a circular society (circular economy)

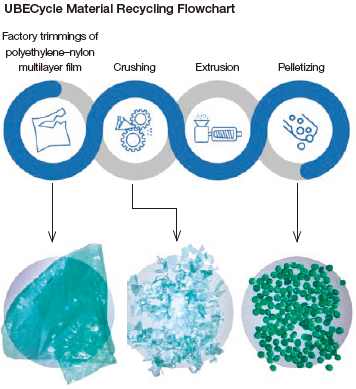

About UBECycle Recycled Multilayer Film

Contemporary social demands and regulations are driving the use of raw materials derived from recycled materials across the industry landscape. Prime examples are the packaging, automotive, electrical, electronics, construction, and other sectors. It is against this backdrop that the UBE Group seeks to recycle offerings incorporating its nylon while drawing on its end-product expertise, partner company network, and technical prowess.

A good example of Group endeavors was UBE Corporation Europe, S.A. Unipersonal (UCE)’s launch of UBECycle. This product is recycled from multilayer film waste. UCE will collect the factory trimmings of the film from film manufacturers to recycle (crush, extrude, and pelletize) them. The UBE Group plans to upcycle materials, including this nylon, for in-house production and commercialization.

UCE has earned certification of this innovative polyethylene–nylon multilayer film from recycling bodies such as RecyClass![]() and APR

and APR![]() .

.

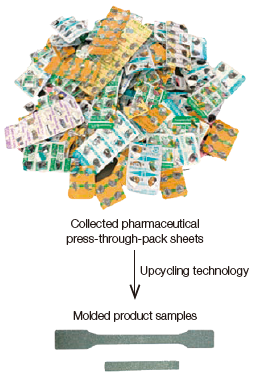

Developing Upcycling Technology for Composite Plastics

As most waste plastics are composites, they cannot be reused in regular recycling processes, so they are mostly incinerated. UBE is developing upcycling technologies for composites, adding new features to aluminum and plastic of pharmaceutical press-through-pack sheets. We are collaborating with aluminum manufacturers and recyclers to create an efficient system to collect these sheets. We are employing proprietary upcycling technology to cultivate applications for the collected sheets.

In coming years, we look to refine our composites upcycling technologies. We will endeavor to grow as a chemicals manufacturer that helps resolve environmental issues, such as by cutting CO2 emissions by reducing the use of petroleum-derived raw materials and tackling marine plastic waste.

Initiatives to nature conservation and restoration (nature positive)

To respond to the conservation of the natural environment (biodiversity) and water resources, we conduct risk analysis at each business site.

Water Risk Assessment Results

We maintain five water risk levels for our key business sites. We take into account information we secure from the World Resources Institute’s Aqueduct water risk atlas and other external sources, as well as by our sites.

Key business sites in Thailand and Spain formulated the following KPIs, and are addressing projected increases in water stress from 2030.

We draw on the Integrated Biodiversity Assessment Tool and local information to check the proximity of key business sites to nature conservation areas and locations that are important for conserving biodiversity and constantly check potential impacts and extents.

- Not near Ramsar Sites

- The sea level near the Ube area is in the International Union for Conservation of Nature’s management category VI for protected areas.

- The Ube-Fujimagari area borders key biodiversity areas (Suonada and the Koto River estuary).

- The national government regulates the seawater area bordering the Ube area, fishing rights there.

Fiscal 2022 Initiatives

Ube Chemical Factory

Marine Plastic Waste

- Participated in year-end street cleanup that an Ube City volunteer group organizes

- Patrolled waste storage sites every quarter

- Recycled waste plastic

Biodiversity Conservation

- Participated in Mine Agriculture, Forestry and Fisheries Office’s forestation initiatives to protect water

- Helped exterminate Argentine ants by contributing to administrative reports and exterminated nests to prevent infestations from spreading beyond business sites

Sakai Factory

Marine Plastic Waste

- Undertook joint cleanups with neighboring companies

Biodiversity Conservation

- Took part in forestation initiative on January 14, 2023

- Attended Osaka metropolitan government and Sakai City government seminars

Water Resource Conservation

- Implemented measures to conserve water, including by installing sensors on office washing basin faucets

UBE Machinery Group

Marine Plastic Waste

- Separately disposed of plastic bottle caps

Water Resource Conservation

- Upgraded waterworks facilities and stepped up wastewater management

Employees participating in the 15th Forest Creation

Employees participating in the 15th Forest CreationExperiential Activity for Water Conservation

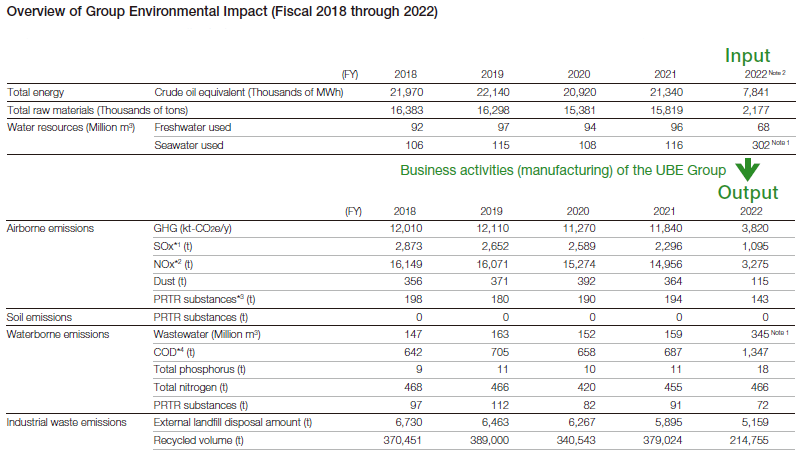

Environmental Performance Data

GHG Emissions

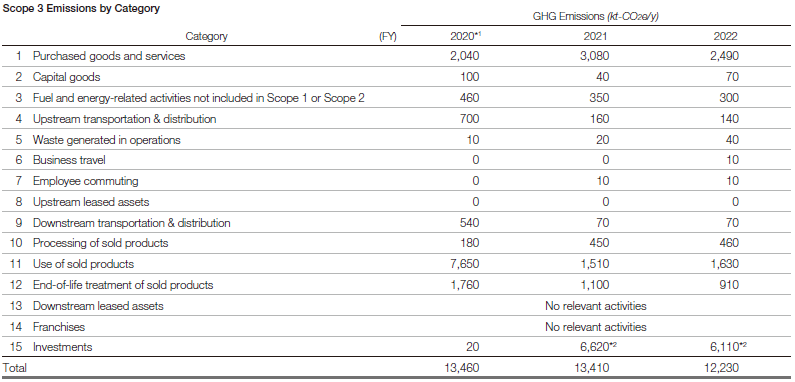

*1 The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.

*1 The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.*2 Data for fiscal 2021 and beyond is aggregated and excludes the former Construction Materials Company.

Note: Numbers may not add up due to rounding.

Note: Numbers may not add up due to rounding.*1 Domestic activities only in fiscal 2020

*2 Category 15 for fiscal 2021 and beyond includes equity-based shares of GHG emissions of Mitsubishi UBE Cement Corporation (former Construction Materials

Company).

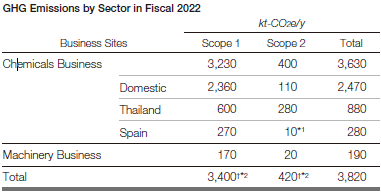

Note: Numbers may not add up due to rounding.

Note: Numbers may not add up due to rounding.*1 Electricity purchased externally is renewables-based.

*2 The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.

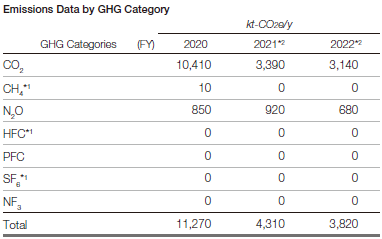

*1 Less than 10,000 t-CO2e/y

*1 Less than 10,000 t-CO2e/y*2 Data for fiscal 2021 and beyond is aggregated and excludes the former Construction Materials Company.

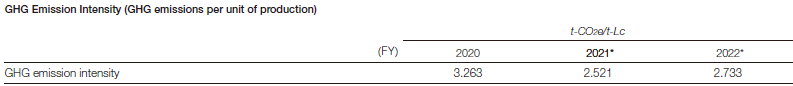

* Data for fiscal 2021 and beyond is aggregated and excludes the former Construction Materials Company.

* Data for fiscal 2021 and beyond is aggregated and excludes the former Construction Materials Company.

Note: Numbers may not add up due to rounding.

Note: Numbers may not add up due to rounding.* Data for fiscal 2021 and beyond is aggregated and excludes the former Construction Materials Company.

* Data for fiscal 2021 and beyond is aggregated and excludes the former Construction Materials Company.

* Data for fiscal 2021 and beyond is aggregated and excludes the former Construction Materials Company.

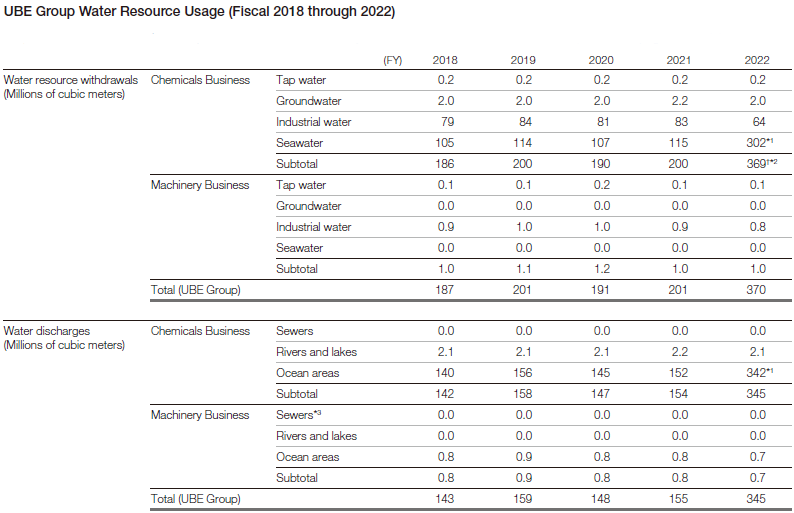

Water Resource Usage

*1 Including cooling seawater for private power generation

*1 Including cooling seawater for private power generation*2 The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.

*3 Wastewater volume 10,000 m3 or less

Response to the Fluorocarbon Emission Restriction Law

Promulgated in April 2015, the Act on Rational Use and Appropriate Management of Fluorocarbons is aimed at reducing leaks of fluorocarbon refrigerants (chlorofluorocarbon, hydrochlorofluorocarbon, and hydrofluorocarbon) to help prevent global warming and the further destruction of the ozone layer. We comply strictly with laws and regulations relating to chlorofluorocarbon refrigeration and air conditioning equipment inspections. We endeavor to prevent fluorocarbon leaks by improving their recovery and filling methods and strengthening equipment operations management.

We are systematically replacing chlorofluorocarbon refrigeration equipment from our processes with alternatives that use low global warming potential hydrofluorocarbons or non-chlorofluorocarbon refrigerants.

*1 The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.

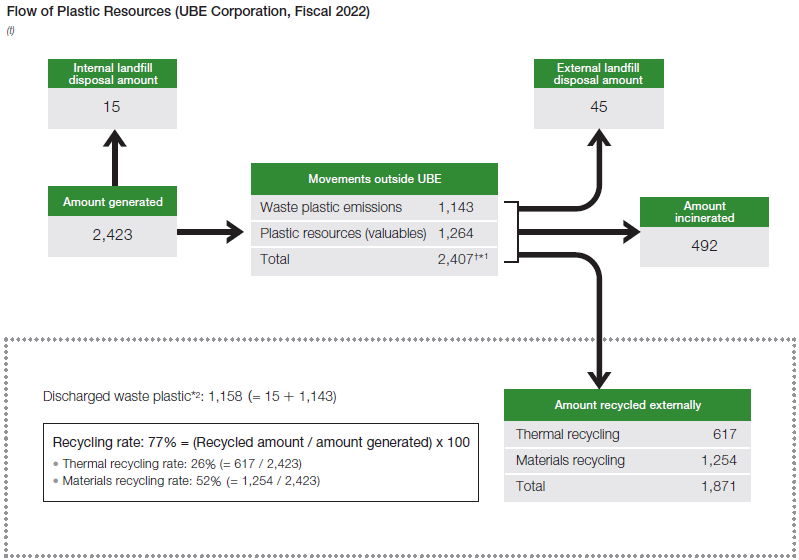

*1 The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.*2 Including in-house internal landfill disposal and recycled amount that are subject to calculation under the Plastic Resource Circulation Act

The Plastic Resource Circulation Act, which went into effect in April 2022, requires businesses to minimize and recycle waste plastic. UBE’s efforts to use plastic resources effectively resulted in a 77% recycling rate in fiscal 2022. We will continue to push ahead with plastic recycling.

Data covers eight UBE business sites. These are the Sakai Factory, Ube Chemical Factory, Ube Chemical Factory Fujimagari Area, Ube Electronic and Industrial Materials Factory, Ube Research Laboratory, Pharmaceutical Research Laboratory, Future Tech Laboratory, and Osaka Research & Development Center.

Environmental Performance

Page 8 of Integrated Report Supplementary Information (Environment and Safety / Quality Assurance) shows water resource withdrawals by source and discharges by destination.

Page 8 of Integrated Report Supplementary Information (Environment and Safety / Quality Assurance) shows water resource withdrawals by source and discharges by destination.Notes:

1. Fiscal 2022 data includes cooling seawater for private power generation.

2. Fiscal 2022 data excludes the former Construction Materials Company.

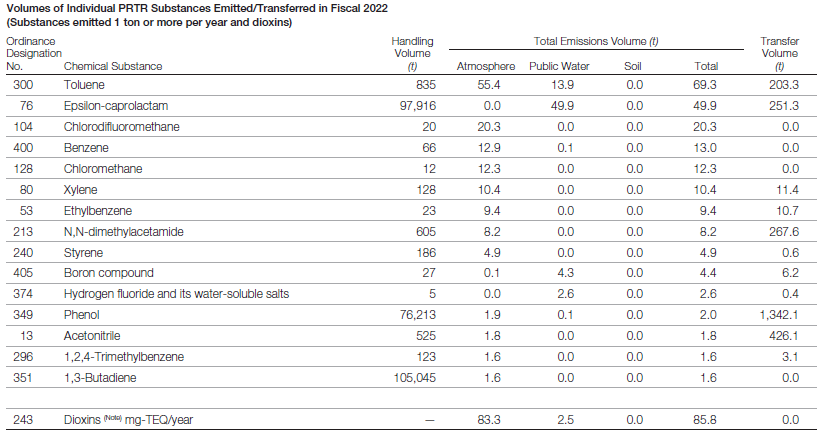

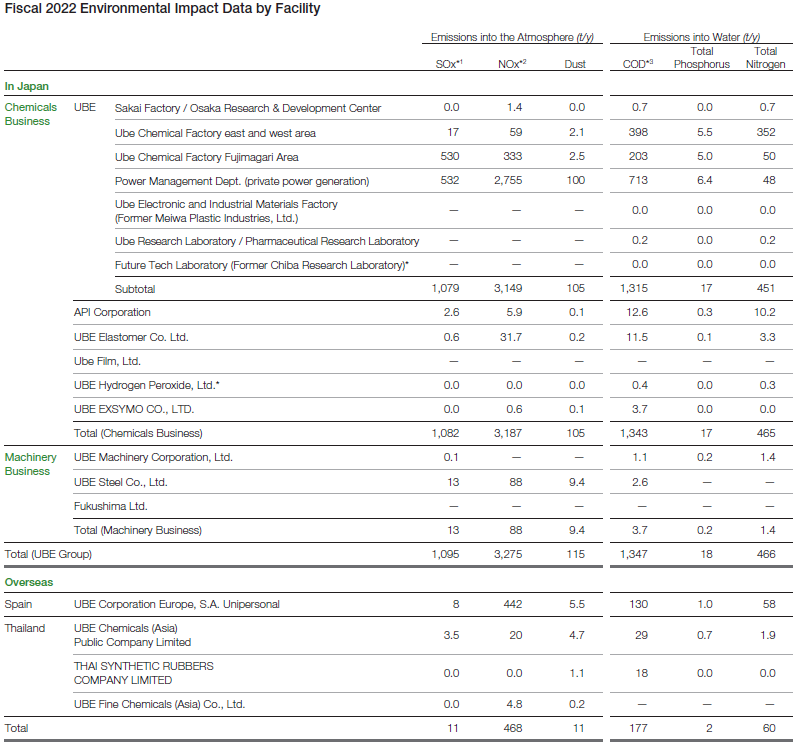

The UBE Group is committed to extensively managing atmospheric and water emissions of pollutants and contaminants, and endeavors to comply with agreements and voluntary standards. We are endeavoring to lower our environmental impact, managing it by checking progress with reduction plans in strategic management meetings and undertaking PDCA cycles. We will keep pursuing business activities that contribute to a circular economy by tackling environmental issues, lowering and using industrial waste, and constraining chemical substance emissions.

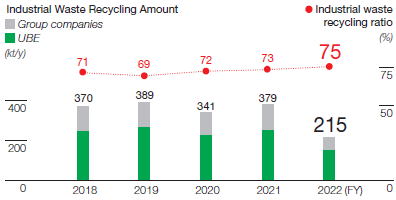

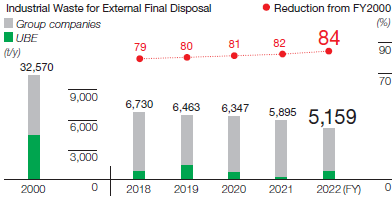

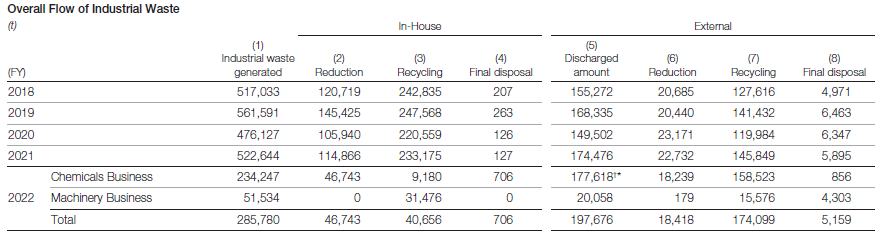

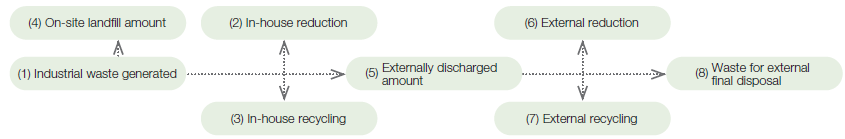

Reducing Industrial Waste

Waste for External Final Disposal

Fiscal 2024 target: 87% reduction from fiscal 2000 level

The UBE Group is reducing and recycling industrial waste to help create a circular economy. Our medium-term goal is to cut external final disposal by 87% from the fiscal 2000 level by fiscal 2024. We have taken steps to reach that target. In fiscal 2022, our external landfill disposal amount was 84% below that of fiscal 2000. We will keep striving to reduce industrial waste.

* The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.

* The figure with “†” mark was assured by the third party assurance. Please see the assurance statement on page 14.Scope of coverage: UBE’s domestic plants and laboratories and key domestic consolidated subsidiaries with plants. See page 16 for details.

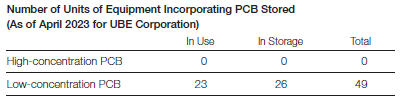

Polychlorinated Biphenyl (PCB) Waste Disposal

We thoroughly audit stabilizers and other equipment using PCBs. In addition, we are endeavoring to complete PCB waste disposals by the deadline set under the amended Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes. We comply with storage and disposal laws and ordinances processing, and utilize Japan Environmental Storage & Safety Corporation (JESCO) and certified detoxification contractors to systematically dispose of PCB waste.

UBE Corporation completely disposed of high-concentration PCB waste in fiscal 2021. It is endeavoring to systematically collect and dispose of all low-concentration PCB waste by the deadline set under the amended Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes.

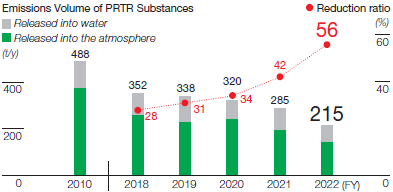

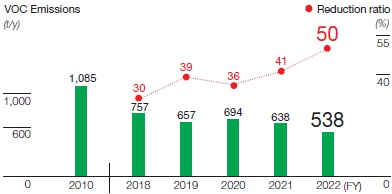

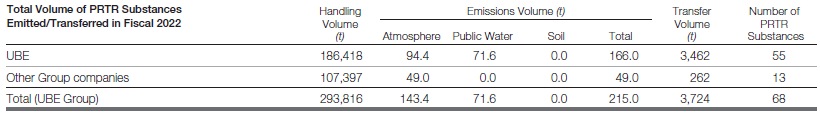

Suppressing Chemical Substance Emissions

Data covers UBE factories, laboratories, and key domestic consolidated subsidiaries with factories shown on page 16 of Integrated Report Supplementary Information (Environment and Safety / Quality Assurance)![]() , representing 70% of such subsidiaries.

, representing 70% of such subsidiaries.

Total Emissions of 20 Chemical Substances

Fiscal 2024 Target: 32% reduction from fiscal 2010 level

The UBE Group accorded Companywide priority to 20 key chemical substances*3 with high emission volumes from among those subject to the PRTR Law*1 and VOCs*2, and endeavors to control their emissions. In fiscal 2022, we reduced the total emissions of 20 chemical substances by 38% from the fiscal 2010 level (in terms of PRTR substances and VOC emissions reductions, as shown above, down 56% and 50%, respectively, from fiscal 2010). The reduction target for fiscal 2024 is 32%. We will continue to cut our emissions.

Note: Contains various compounds

Note: Contains various compoundsScope of coverage: UBE’s domestic plants and laboratories and key domestic consolidated subsidiaries with plants (see page 16), representing 70% of such subsidiaries

- *1 Pollutant Release and Transfer Register (PRTR) Law: This legislation requires companies to identify business site chemical substance emissions and transfer volumes and report to the government. The Ministry of the Environment discloses the submitted information on its website. Such disclosure is designed to encourage voluntary efforts to improve chemical substance management.

- *2 Volatile organic compounds (VOCs): These organic chemicals evaporate or sublimate easily, entering the atmosphere as gases. They are factors in the forming of suspended particulate matter (PM) and photochemical oxidant pollution.

- *3 20 chemicals selected independently: Methyl alcohol, butyl alcohol, toluene, epsilon-caprolactam, styrene, ammonia, cyclohexane, cyclohexanone, oxalic acid, vinyl acetate, xylene, n-hexane, ethylbenzene, chloromethane, benzene, dimethyl phthalate, N,N-dimethylacetamide, boric acid compound, phenol, hydrogen fluoride and its water-soluble salts

* These sites reorganized or changed their names in fiscal 2023. See Reorganizations and Renamings on page 16 for details.

* These sites reorganized or changed their names in fiscal 2023. See Reorganizations and Renamings on page 16 for details.Scope of coverage: UBE’s domestic plants and laboratories and key domestic consolidated subsidiaries with plants (see page 16), representing 70% of such subsidiaries

- *1 Sulfur oxides (SOx) originate in the sulfur (S) component of fuels. Boilers are our main source of these oxides.

- *2 Nitrogen oxides (NOx) stem from fuel combustion, primarily from Group boilers and cement kilns.

- *3 Chemical Oxygen Demand (COD): This is an indicator of water pollution by organic substances and represents the amount of oxygen consumed in the chemical oxidation of organic matter.

Internal Carbon Pricing

The UBE Group sets internal carbon pricing as a guideline for evaluating carbon prices in capital investment.

| Objectives |

|

|---|---|

| Start date | April 1, 2010 |

| Targeted greenhouse gas | Energy-related CO2 |

| Listed items | Increase/decrease in CO2, economic indices when CO2 is considered (CO2 increase/decrease of 1,000t-CO2 or more per year) |

| Materials and text covered |

|

| Carbon price | 10,000 yen/t-CO2 (~FY2023) However, notifications will be issued as needed in the even of significant changes brought about by regulatory trends, etc. Carbon pricing subject to change. |